The sight of the Lucas well at Spindletop in 1901 spewing oil into the sky became a tragically misunderstood trope in which “gusher” has become synonymous with drilling success. Anyone in the oil & gas extraction business knows, however, that a gusher, or blowout, is a failure of epic proportions that puts people and the environment at high risk. We are laser-focused in the industry to prevent such catastrophic events, deploying advanced pressure control systems and continuously monitoring data streaming from the rig for any early warning signs. But blowouts, washouts, twist-offs, and a myriad of other train wrecks still happen. Why?

Drinking from the Firehose

Even with all the data at our disposal during drilling, the tasks of processing, synthesizing, and searching data for early warning signs of a washout or other catastrophic event are largely manual and human-based. A single engineer or even a room full cannot interpret and correlate disparate streams of real-time data fast enough. Staff often split their attention among multiple ongoing monitoring tasks, further reducing the ability to spot and respond to changing conditions.

For example, identifying a washout before a sudden pressure drop or a twist-off requires constant attention to high-frequency standpipe and off-bottom pressures. Connection events can be missed. Relying on traces alone makes it very difficult to identify a gradual decreasing trend in standpipe pressure over a long period.

Mining Data for Early Warnings

Raising the bar on effective hazard avoidance methods requires automating data analysis and taking people out of the loop until action is required. Monitoring by exception algorithms does all the heavy lifting when it comes to processing rig data, with the added benefit of enabling staff to apply more focused attention to issues after an alert is received.

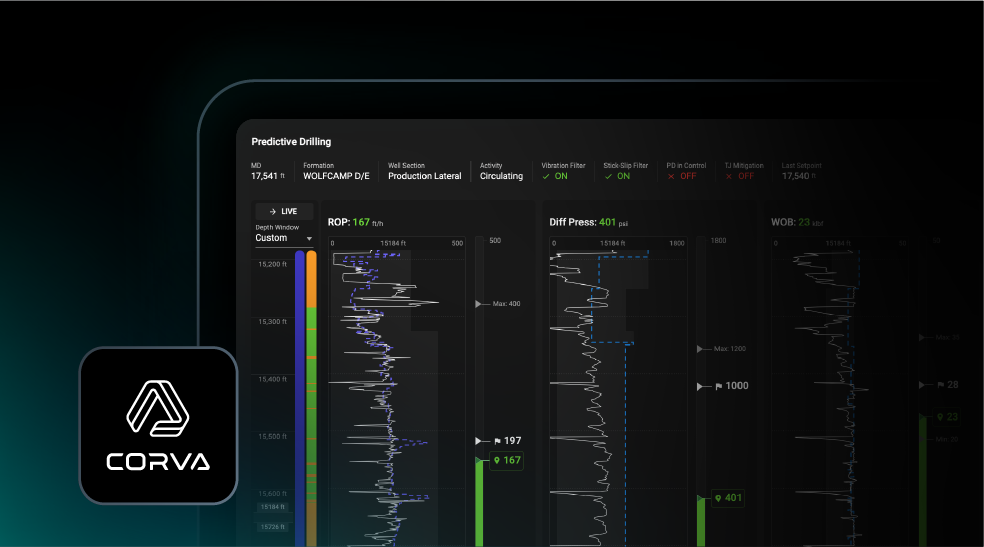

Sticking with our washout example, Corva’s alert algorithm can monitor multiple pressure data streams in real-time, including stabilized off-bottom pressure. If two consecutive dropping standpipe pressure values are detected, an alert is triggered to notify rig and back office users who can then take appropriate action.

Putting a Value on Alerts

Preventing a washout before a costly twist-off can save an oil & gas producer hundreds of thousands of dollars. Recently, one of Corva’s clients successfully identified four downhole and 4 surface equipment washouts using our smart alerts. Plus, engineering staff were able to spend more time interpreting each situation they were alerted to. But beyond the economic savings, what is the value of dramatically improving safety and productivity? Priceless!