Throughout history, many industrial sectors including mining, agriculture, manufacturing, and now oil & gas, are faced with the dilemma of scaling the supply chain to increase production. Let’s use a factory as an illustration of our main points. Factories add assembly lines, automate processes, and reduce bottle necks to increase efficiency in their system. Production outputs and time are two main variable that validate system upgrades. The question is, how do you grow your output when your factory is spread over hundreds of acreages of land? Now image this factory spanning between county and state lines. This dilemma is a huge undertaking for an industry that relies so heavily on production output to stay in business. This is factory drilling and Corva believes is the future of the Energy sector.

Let’s consider the Permian Basin; there is a high degree of understanding in where the sweet spots are. The drilling and production teams are tasked with extracting the highest quality of resources using efficient drilling and production measures. Wall street measure upstream organizations by the number of barrels produced per day for a certain initial period of production. To continually meet investor expectations output must continue to grow, sometimes nonlinearly. Top companies will seek exponential growth models as they seek industry domination. A company’s ability to scale must be tempered with optimal use of input resources. You can expect once the leaders figure it out, the rest of the pack will follow. The future of oil is a factory scale model.

How is scale achieved?

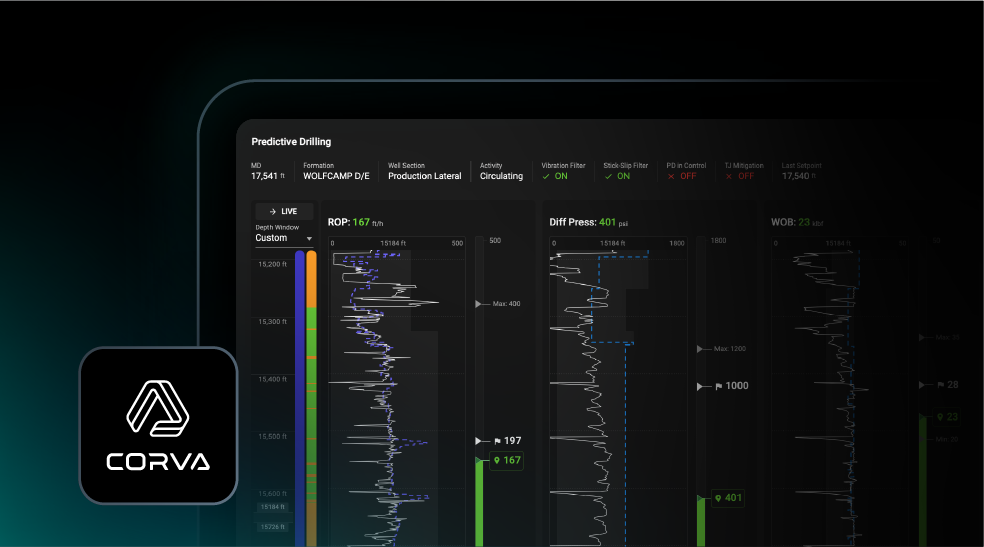

Leading oil companies will gradually grow into data companies. EOG Shows Why It’s The ‘Apple of Oil’ With Gusher Of Mobile Apps, Data. Each new piece of data can potentially optimize the factory line. Analytics lead to more predictable and less expensive resource extraction.

Pad drilling is the concept of using a shared platform to construct multiple wellbore sections. Essentially, this becomes the drilling “factory” standard. Rig counts historically grow as production outputs increase. More rigs lead to more challenging logistics and operational management. How do you avoid problems and share learning across multiple teams when the benchmark is 3-4 days of drilling per well? A company will need to efficiently control these rigs with the same processes and KPIs — in a collaborative way. Companies using a decentralized model of drilling without analyzing real-time analytics hit production output roadblocks because they are not capturing useful information from their drilling programs. By comparison, look at factory assembly lines still using people versus those automated with machines. That’s where a software platform becomes such an important facet to optimize the operation.