$5 million USD, that’s what one Corva client estimates they save annually by using our drilling optimization platform just to optimize connection times. Corva helps save oil and gas producers big across the rig by optimizing ROP and nonproductive time, extending BHA life, and avoiding costly hazards and downhole remediation. In addition to optimizing field costs, Corva’s real-time drilling optimization platform is laser-focused on delivering the best well possible, precisely guiding wellbores in the pay zone, and maximizing production potential.

Corva is used by most of the supermajors and smaller operators, onshore and offshore, and by conventional and unconventional producers. Our technology is deployed on rigs worldwide. Corva can scale to meet the needs of any drilling project with our on-demand cloud that captures 1.2 terabytes of data every day, a suite of 65 field-hardened engineering apps, and a continuously staffed customer operations center comprised of drilling optimization experts.

From drillers and crews to back-office engineering and remote monitoring centers, Corva provides the data and analytics your team needs to optimize drilling in real-time. Here are just 7 of our apps that will help you drive drilling efficiency to the next level.

Driller’s Roadmap

Corva’s DRM seamlessly brings historical well and BHA data together to allow your team to easily identify optimal drilling parameters for a given formation. It is used to set the starting weight on bit, torque, RPM, and other parameters for formation tops using best-in-class performance and BHA configuration.

Figure 1: Corva’s Driller’s Roadmap

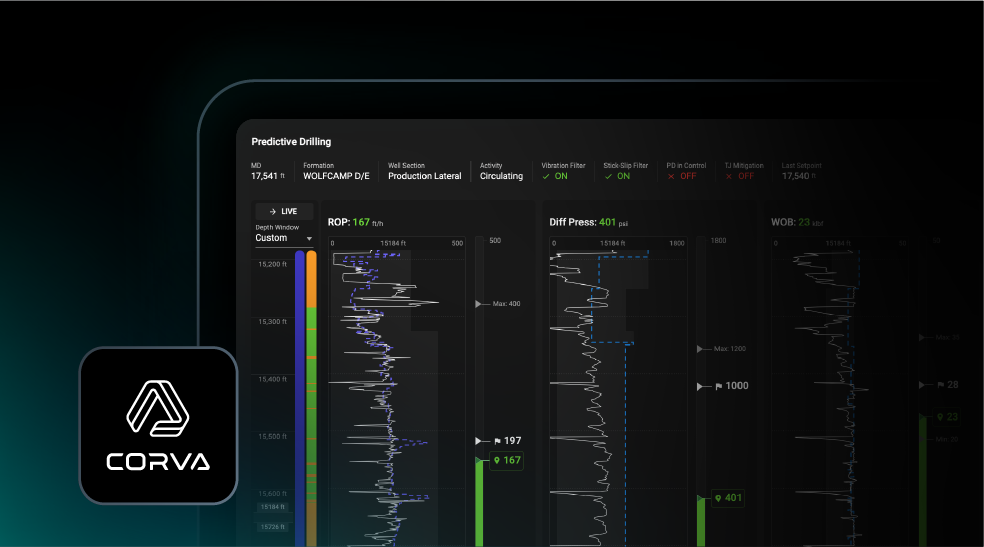

Parameter Comparison

Once best-performing wells and parameters by formation have been identified, the Parameter Comparison app enables drillers to stay on target with instant feedback on deviation from the best-performing well’s RPM, WOB, Torque, MSE, etc. With “Look Ahead” enabled, users can anticipate upcoming parameter adjustments and formation transitions.

Figure 2: Corva’s Parameter Comparison App

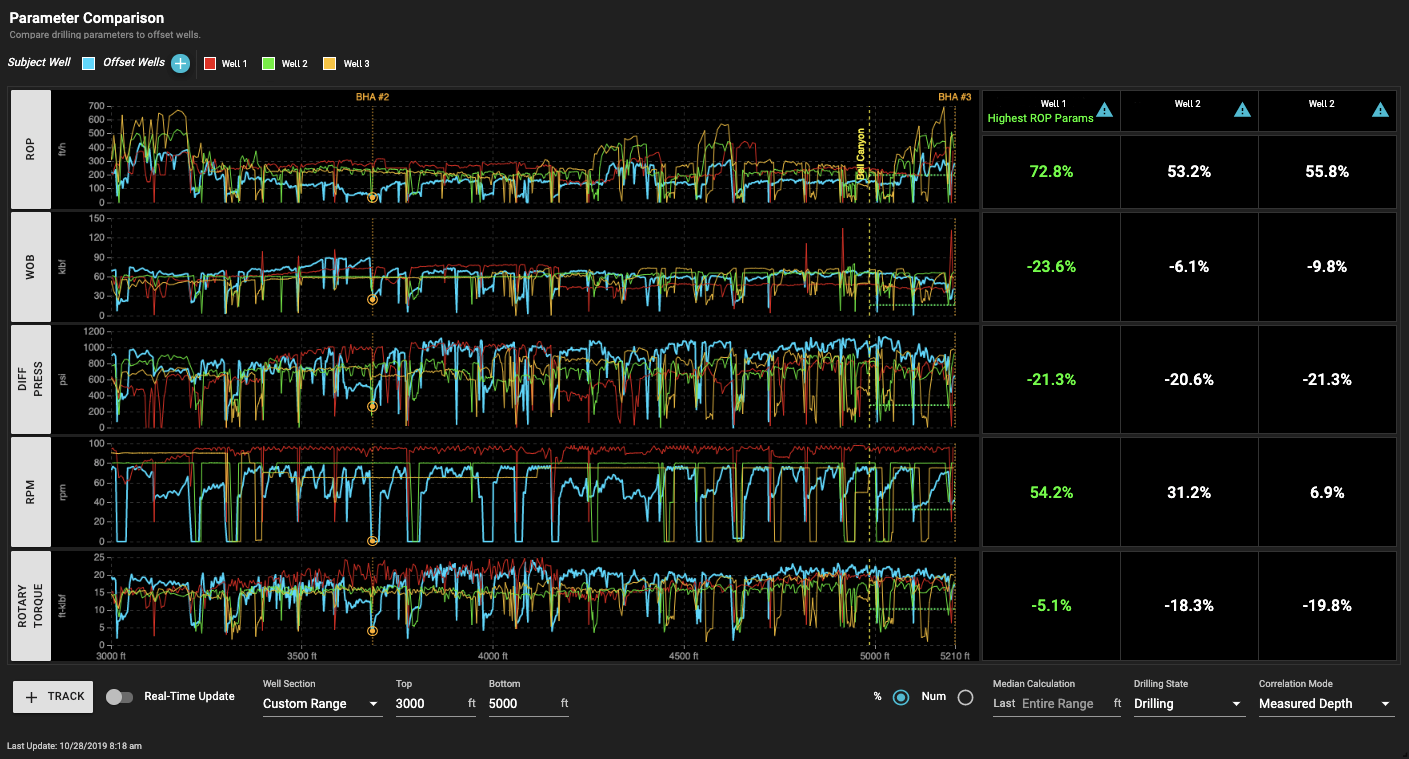

Days vs. Depth

Corva’s DVD app replaces the static plots engineers often rely on with a data-driven Days vs. Depth screen that provides the overall picture of drilling time and costs compared to what was planned for the current well. Importantly, it overlays the DVD plot for best-in-class offsets, which reaffirms that the target is matching historical performance.

Figure 3: Corva’s Days vs. Depth App

ROP and MSE Heatmaps

Best used in intermediate and production sections, Corva’s ROP and MSE heatmaps maximize ROP and extend bit life by enabling users to rapidly respond to changing subsurface conditions with red, yellow, and green color-coding that highlight optimal drilling parameters for WOB, Diff, and RPM. Heatmaps are included by default on Corva’s pre-built Drilling Efficiency Dashboard.

Figure 4: Corva’s Drilling Efficiency Dashboard

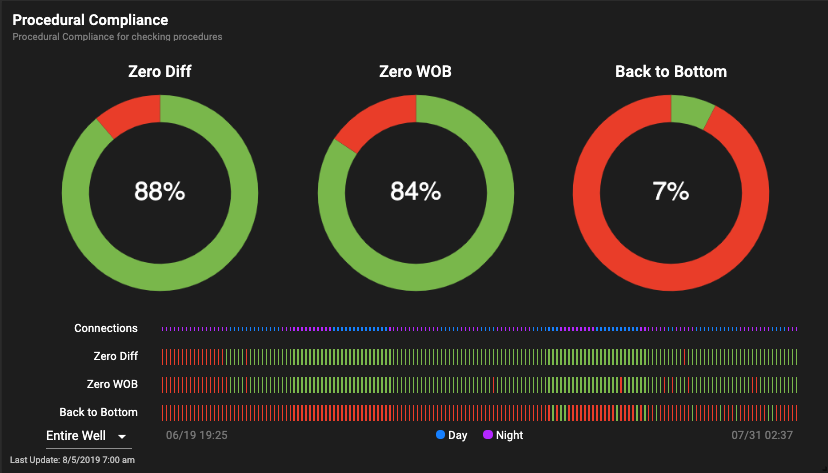

Procedural Compliance

From connections and tripping to equipment calibration and malfunction, your team maintains dozens of standard operating procedures to drive efficiency and consistency. Corva’s real-time drilling optimization platform lets your team define organizational and industry standards for simple or highly complex procedures, and then enforce them with our Procedural Compliance app and automated alerts.

Figure 5: Corva’s Procedural Compliance App

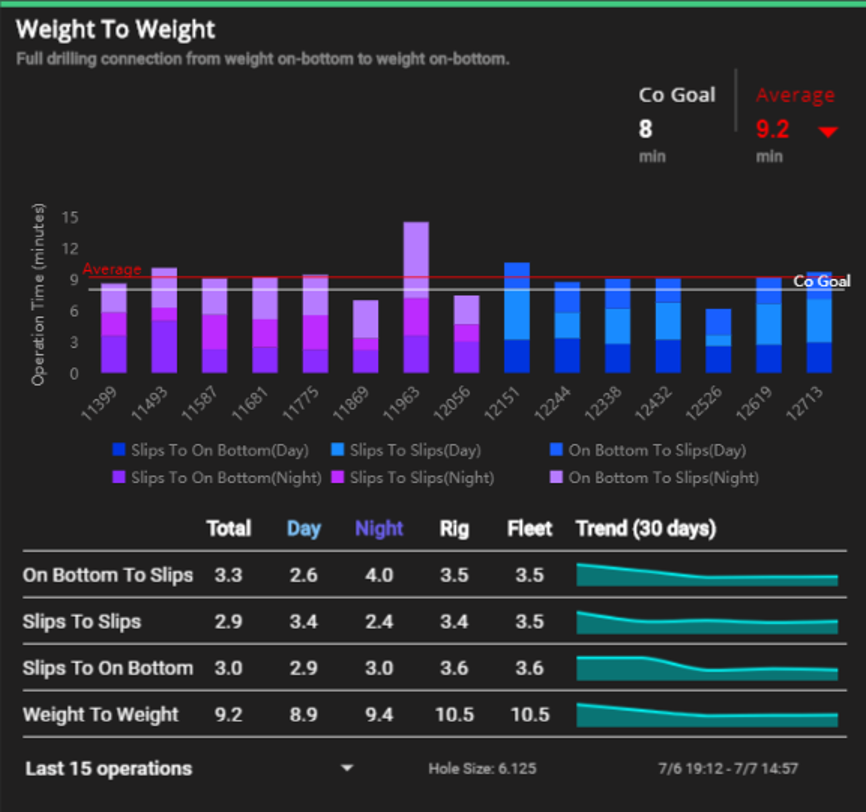

Connection Times

Corva’s Connection Times app automatically tracks on bottom to slips, slips to slips, slips to on bottom, and weight to weight. At a glance, users see the times for the current operation and averages for the day, rig, and fleet with a 30-day trend. It provides valuable KPIs for crews that can trim significant time and money on connections.

Figure 6: Corva’s Connection Times App

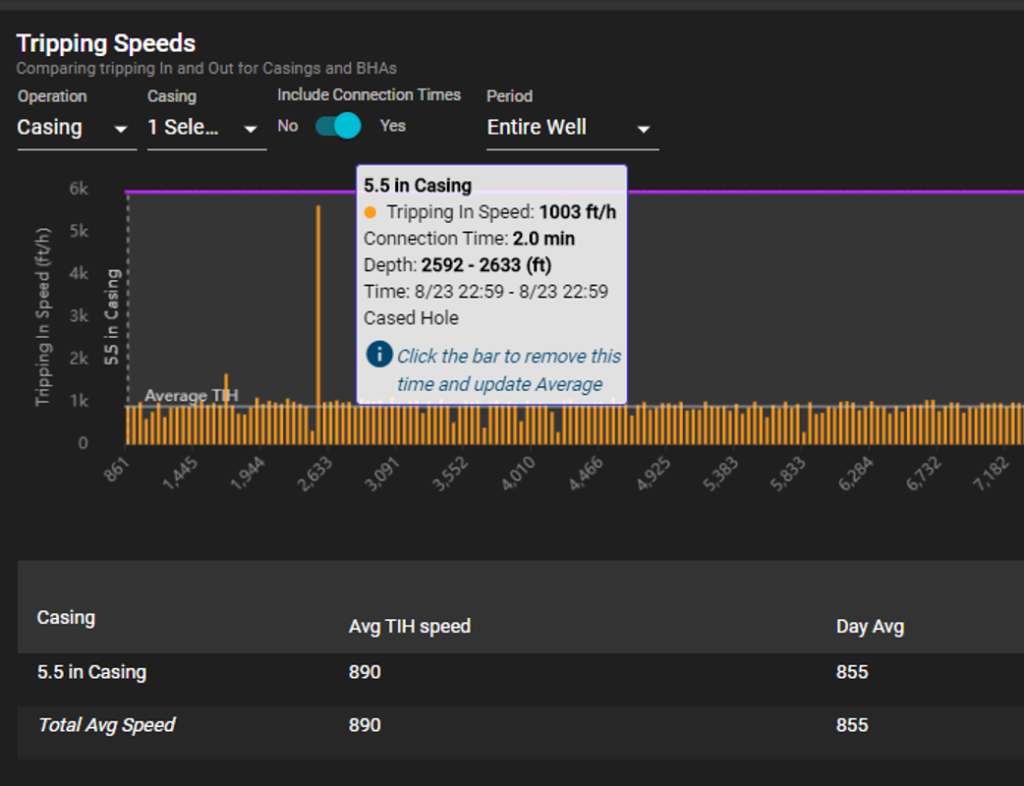

Tripping Speeds

Trimming down tripping time for BHAs can add up to significant operational efficiency and savings on rig time. Corva’s Tripping Speeds app allows users to set goals then track KPIs for tripping in and out BHAs with the ability to compare day and night shifts. Analyze connection times alongside tripping speeds with a bar chart break down of individual joints or stands. The app provides similar functionality for tripping in casing.

Figure 7: Corva’s Tripping Speeds App

Key Takeaways

For many companies, drilling optimization is a moving target. Scattered datasets, lack of consistency among crews and equipment, and manual data analysis impede real-time optimization. With Corva, your team gains powerful capabilities to centralize drilling data, automatically capture KPIs, implement best practices, and enforce standards, all in real time. The result is a loop of continuous improvement that drives drilling performance higher and reduces field costs.