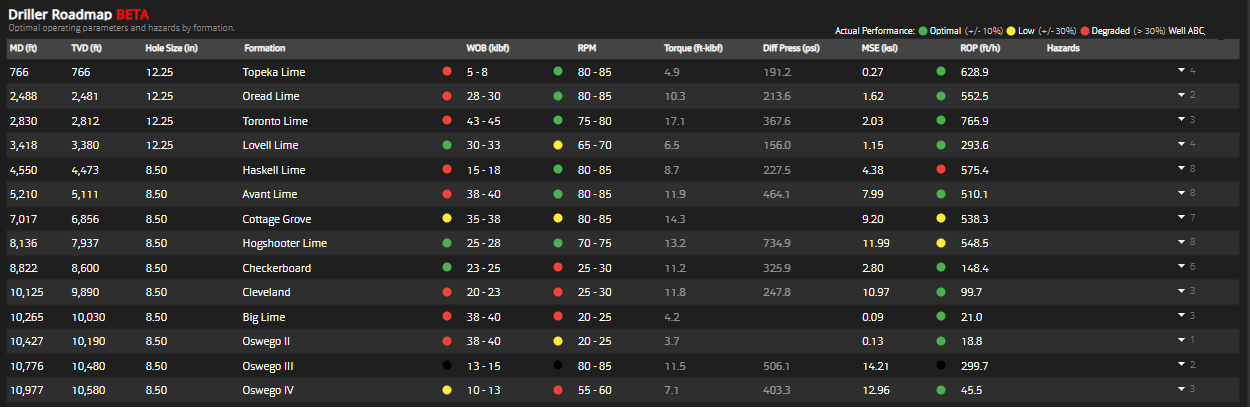

The current best practice for the selection of optimal drilling parameters is to generate complex spreadsheets for static results of formation parameters. These recommended operating parameters are obtained either by manually analyzing offset wells and/or from the bit manufacturer’s database. The Drillers Road Map, or DRM, provides recommendations by formation for WOB and RPM that are used to guide the driller like a road map.

Corva has developed an automated DRM that allows users to efficiently mine offset well data by replacing the manual process. Users spend time analyzing DRM results from offset wells instead of manipulating and processing data merely to produce the DRM.

The value to drilling engineers is significant time savings for a given number of offset wells or the ability to access more offset wells than previously possible in a given time. A drilling engineer recently told Corva,

“The drillers went out of their way to tell me they really like the Driller Road Map over the past few days of using it. They can see what they may have been doing differently on other wells.”

The DRM also delivers value to drillers by providing the best starting point for WOB and RPM parameters for each formation.

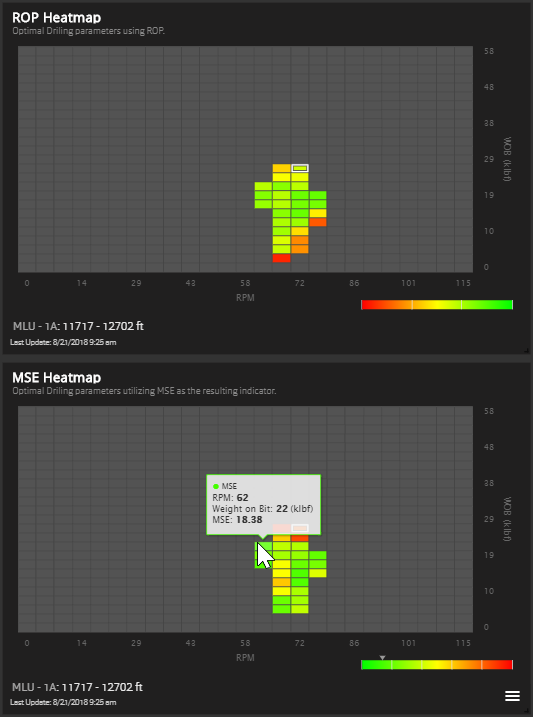

As each new formation is penetrated it is desirable to continuously adjust WOB and RPM for changing conditions since every well is different. Current standard practice is to use ROP heatmaps that show recent actual ROP for the various WOB and RPM combinations used. Corva offers both ROP and MSE heatmaps that look back at up to 1,000 feet drilled and reset automatically with each new formation penetrated.

Therefore, the current workflow for obtaining optimal drilling parameters using Corva is to auto-generate the DRM from offset wells and then adjust WOB and RPM using real-time ROP and MSE heatmaps. In the future, real-time drilling parameter optimization will be extended to account for rotational tendencies to help minimize sliding and bit dysfunctions such as wear, vibration, and balling.